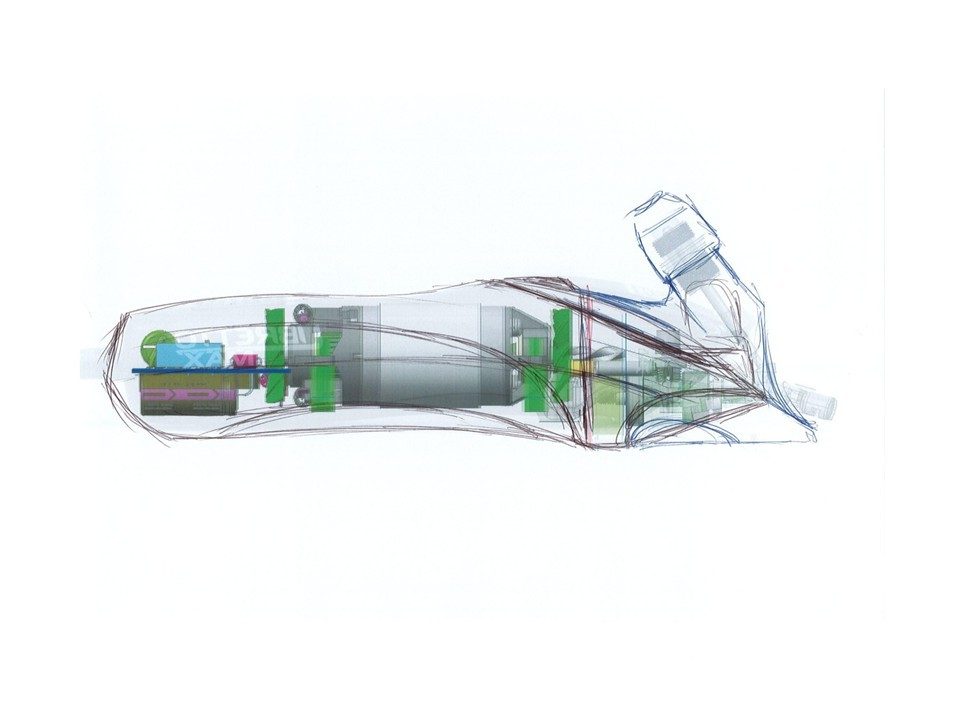

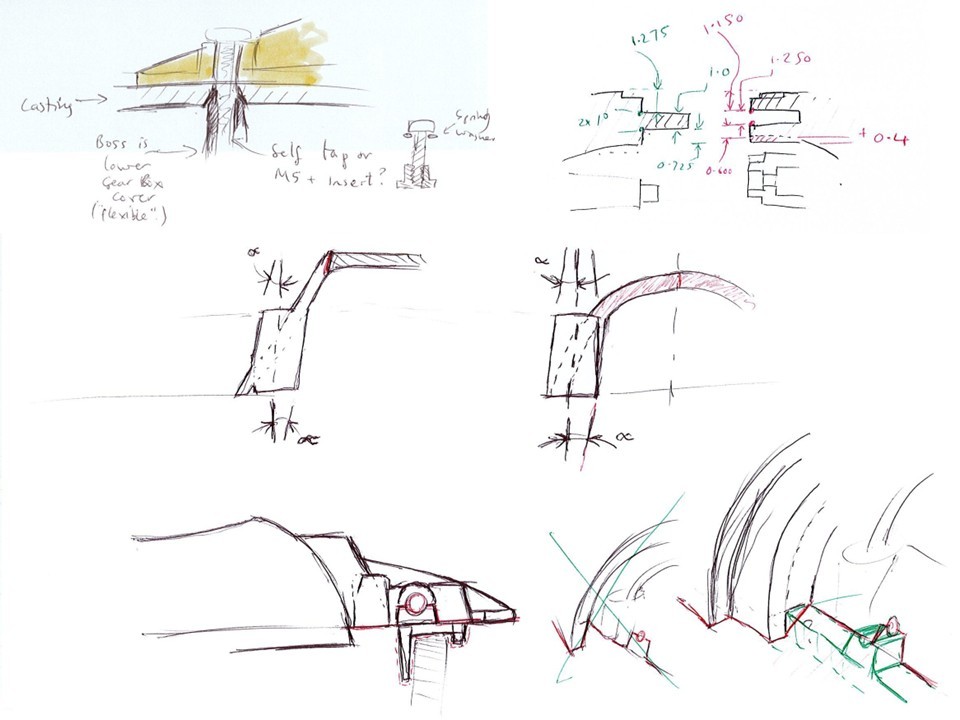

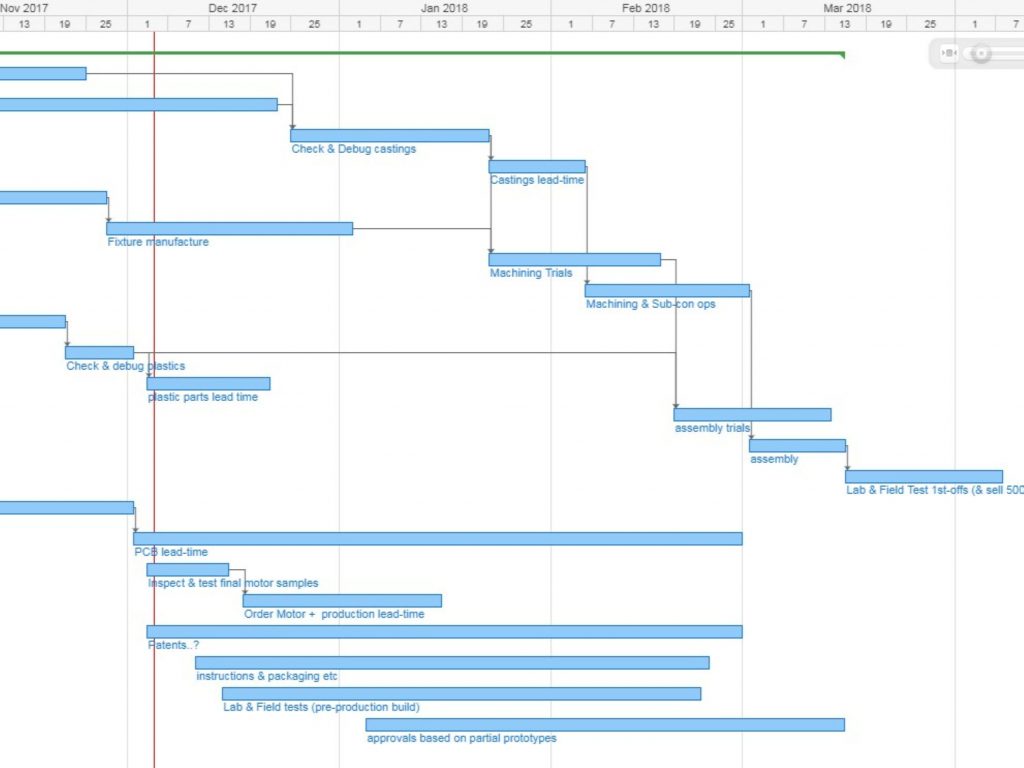

Designed from scratch in parallel with the Fusion Clipper (with which it shares a modular motor & handle), the Fusion Shear contains a number of innovations which were successfully patented. I was hands-on lead for the engineering & industrial design, utilising a mixture of parametric surface- & solid-modelling techniques in NX to balance the ergonomic handle with the electro-mechanical internals. Managing a small in-house team, I was also responsible for the engineering timelines and the technical documentation (drawings & BOMs etc).

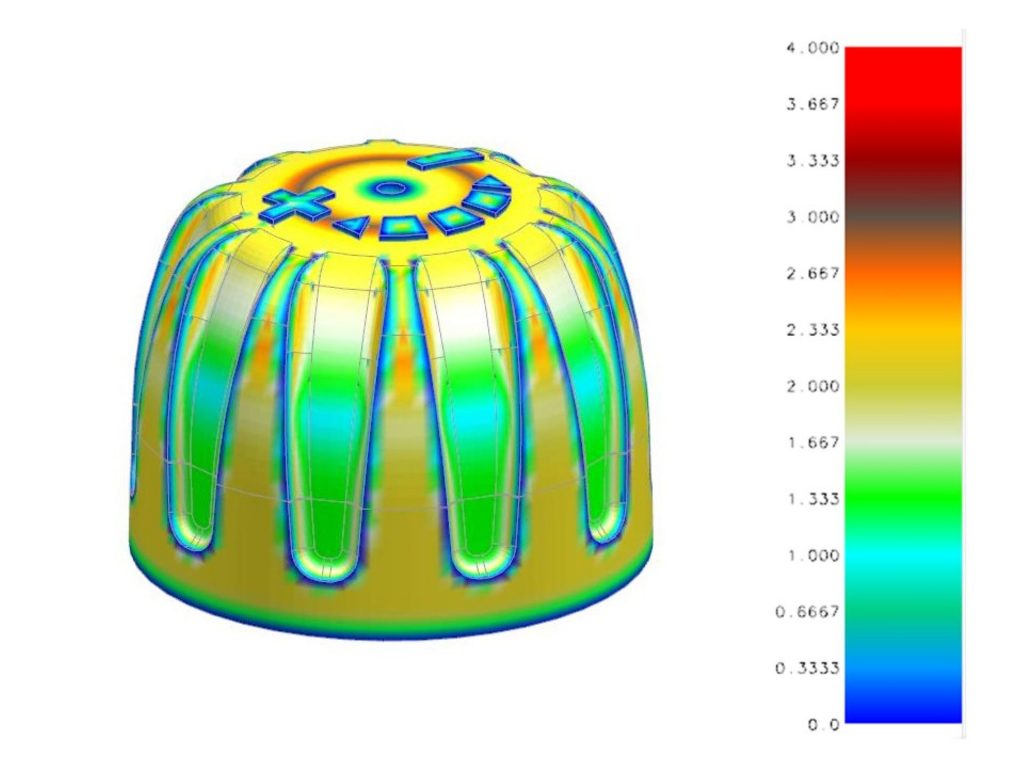

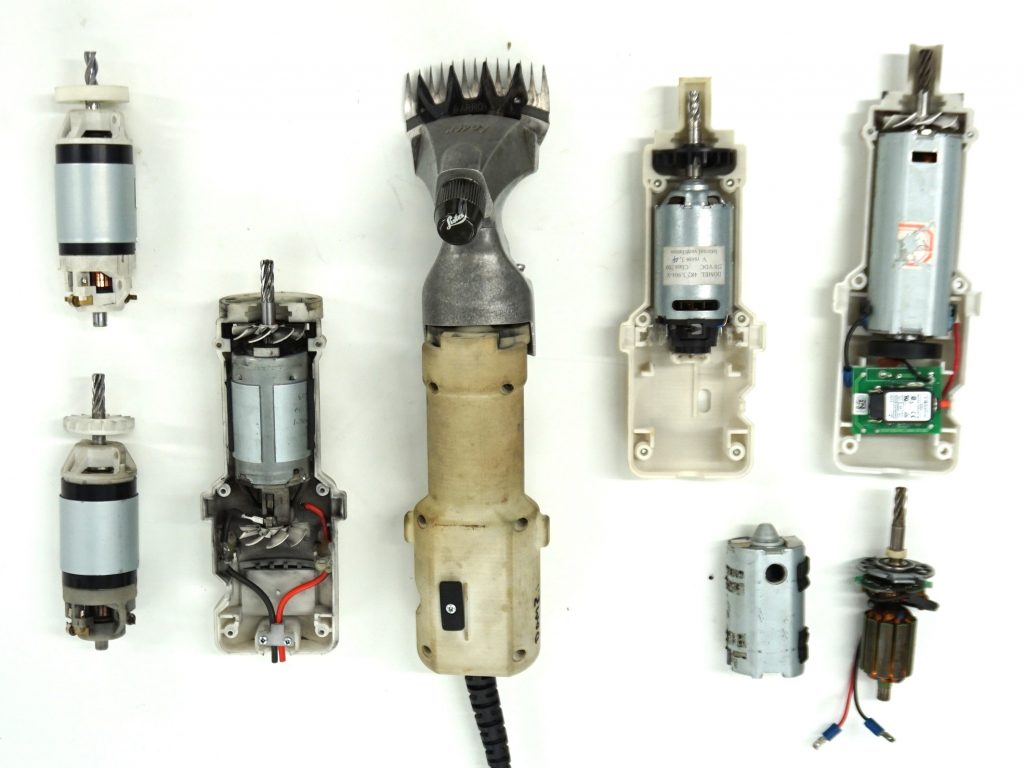

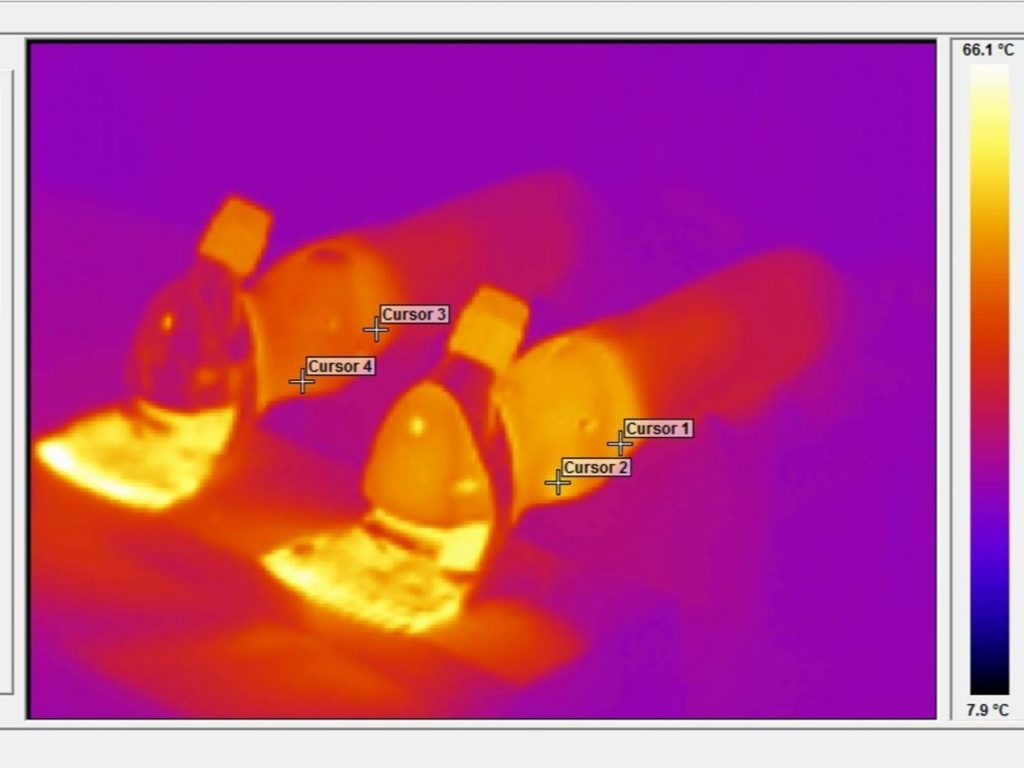

Finding the right motor was incredibly challenging. I helped source and test a number of standard motors before we partnered with a supplier that was able to offer extensive customisation: The winding was tuned to match our speed-torque requirements, bearings and brushes were upgraded for durability, a bespoke sub-frame was designed to drop straight into our handle, and a unique dual-fan system was employed to ensure cool running.

I collaborated with our PCBA designer to optimise the layout, and worked closely with our in-house manufacturing team to define machining fixtures and assembly jigs. I liaised directly with component suppliers to source the new mouldings & castings within budget, subsequently approving their DFM’s & tool-layouts, reviewing FAI reports, then inspecting and signing-off samples for form/fit/function & CMF before mass-production. I organised and attended field-trials to test the prototypes and end-product, as well as working with external partners to arrange the various compliance & certification tests and the patent applications.