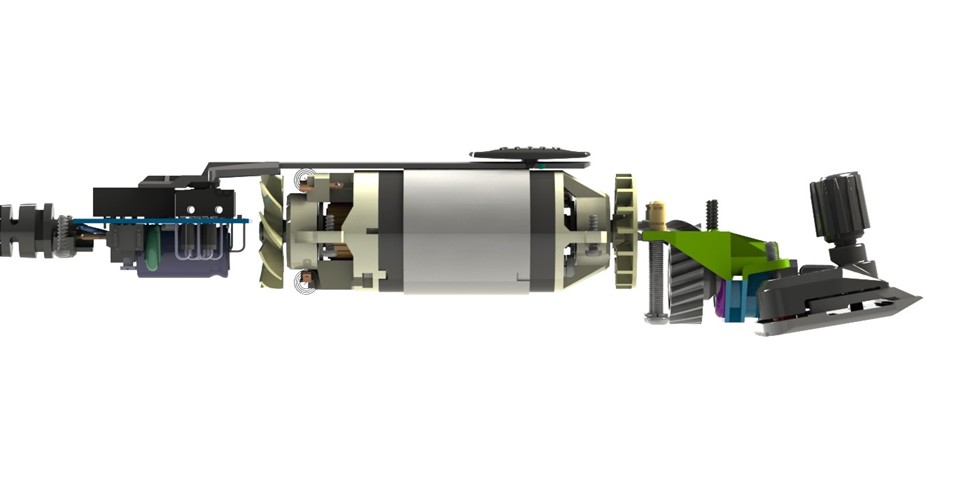

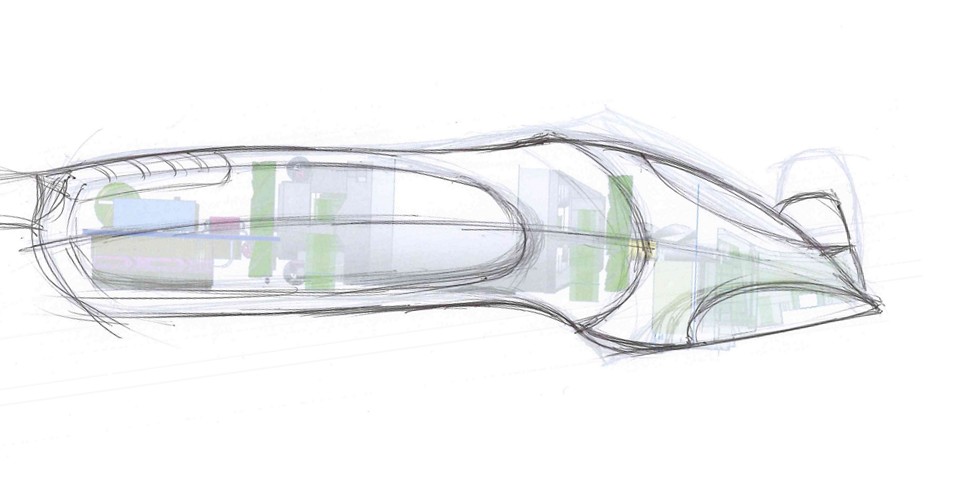

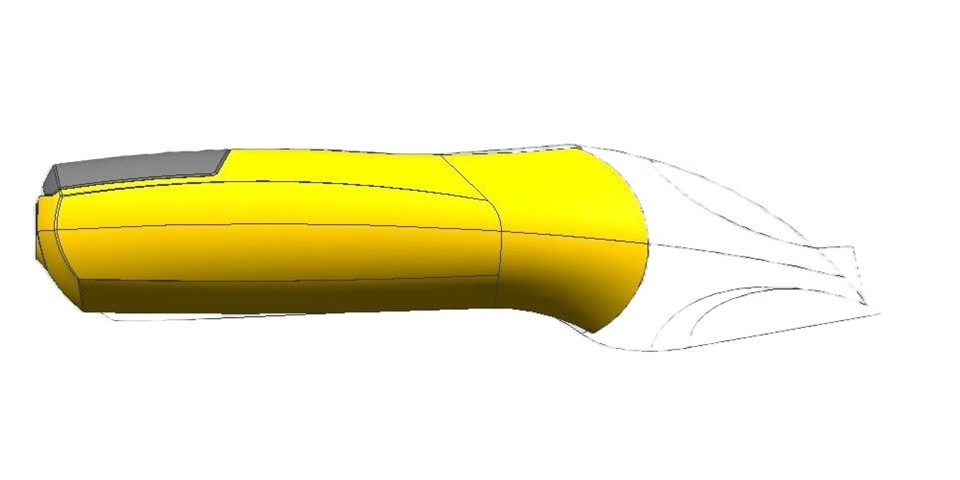

Designed from scratch in parallel with the Fusion Shear (with which it shares a modular motor & handle), the Fusion Clipper contains a number of innovations which were successfully patented. I was hands-on lead for the engineering and for the industrial design of the shared handle, utilising a mixture of parametric surface- & solid-modelling techniques in NX to balance the ergonomics with the electro-mechanical internals. Managing a small in-house team, I was also responsible for the engineering timelines and the technical documentation (drawings & BOMs etc). I collaborated with our in-house industrial designer to optimise the new gearbox design, as well as the blade-mounting plate and tension nut which were both to became modular components for future clippers.

I worked closely with our in-house manufacturing team to define machining fixtures and assembly jigs. I liaised directly with component suppliers to source the new mouldings & castings within budget, subsequently approving their DFM’s & tool-layouts, reviewing FAI reports, then inspecting and signing-off samples for form/fit/function & CMF before mass-production. I worked with external partners to arrange the various compliance & certification tests and the patent applications. I also organised and attended field-trials to test the prototypes and end-product under some extreme conditions.