Elvie’s ‘Stride 2’ paired an existing pump with all-new breast-cups; these incorporated multiple innovations to improve comfort, discretion, ease of assembly, cleanability and reliability. Reduced part-count & cost enabled extra sizing options to be included, to cater for 99% of women.

As Design Manager for a small team of design engineers, I adopted a hybrid role by sharing in some of the design & engineering tasks. When I joined the project, the concept was already well defined, but significant technical challenges remained. With the tooling-order deadline fast approaching, I encouraged the team to overcome these challenges by pivoting to more pragmatic design options, rather than trying to patch-up some ambitious but risky geometry. This allowed us to rapidly overcome multiple reliability and mouldability issues, unlocking the timeline, turning a troubled concept into a fully-tooled product within 6 months.

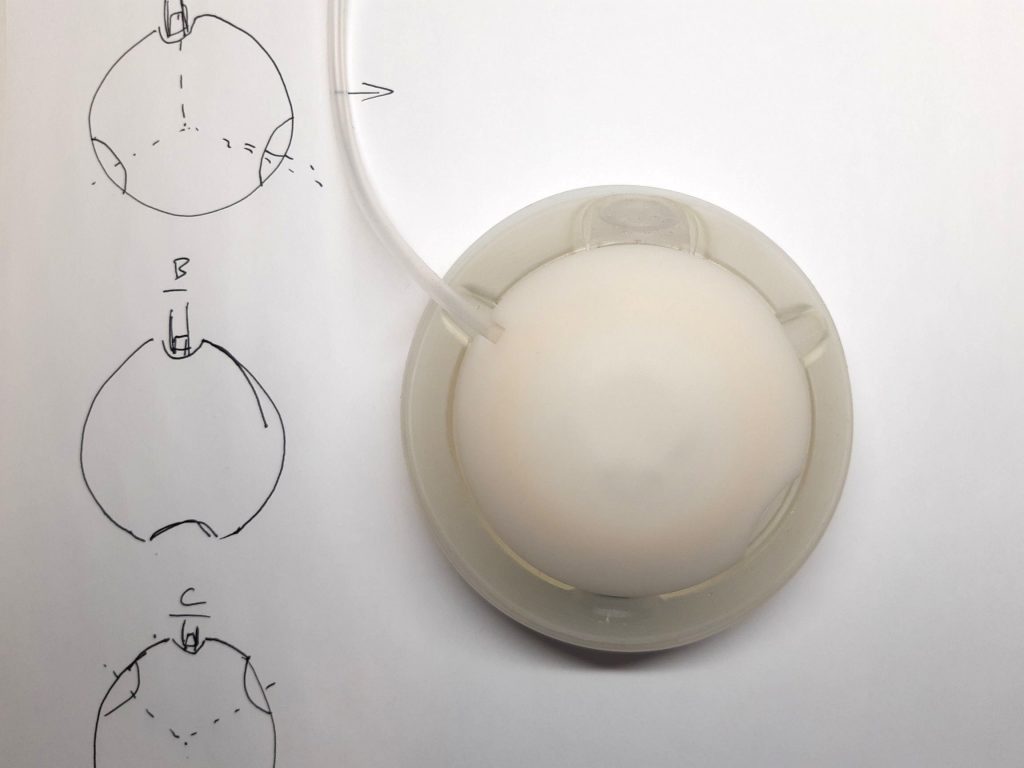

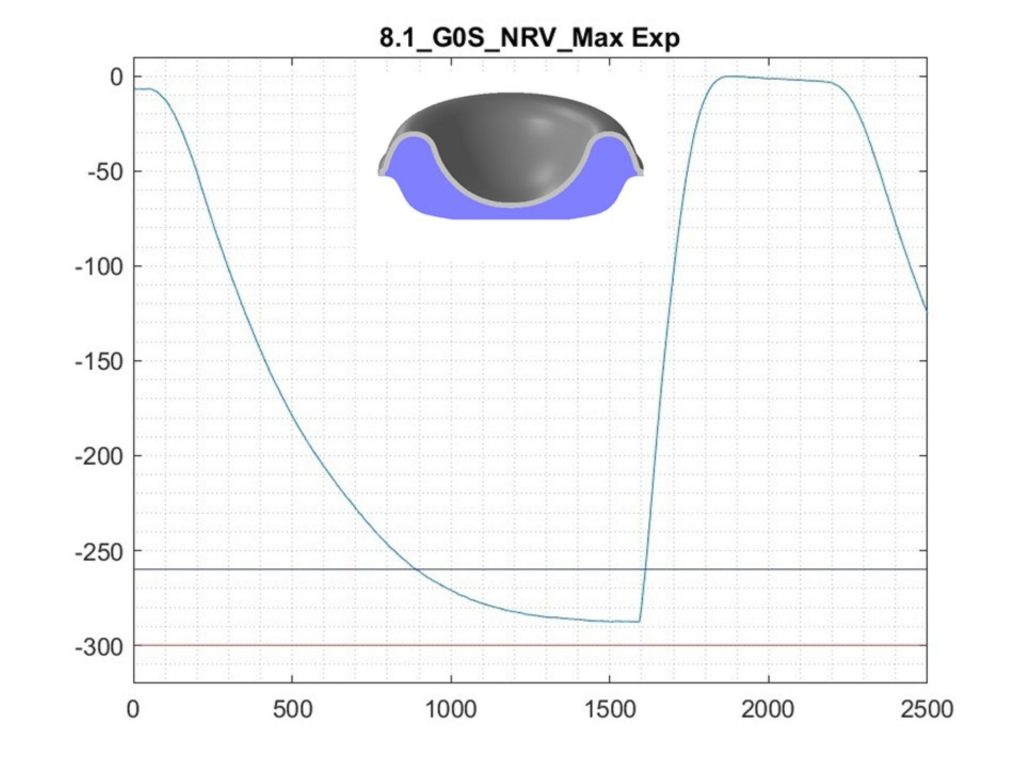

One area where I was particularly hands-on was the design of the diaphragm; this was uniquely challenging due the dynamic pressure targets it had to achieve during pumping. I created parametric CAD models which could easily be manipulated to output multiple designs, I also commissioned a couple of simulations which the team could use to predict the static and dynamic pressures achieved by each design. Short-listed designs were hand-moulded by myself in vac-casting tools which I designed & 3D-printed, then pressure-checked in test-rigs which I also designed & made. By combining these simulations with selective prototyping & testing, we vetted >150 geometries and tested a dozen prototypes until the winner quickly emerged.

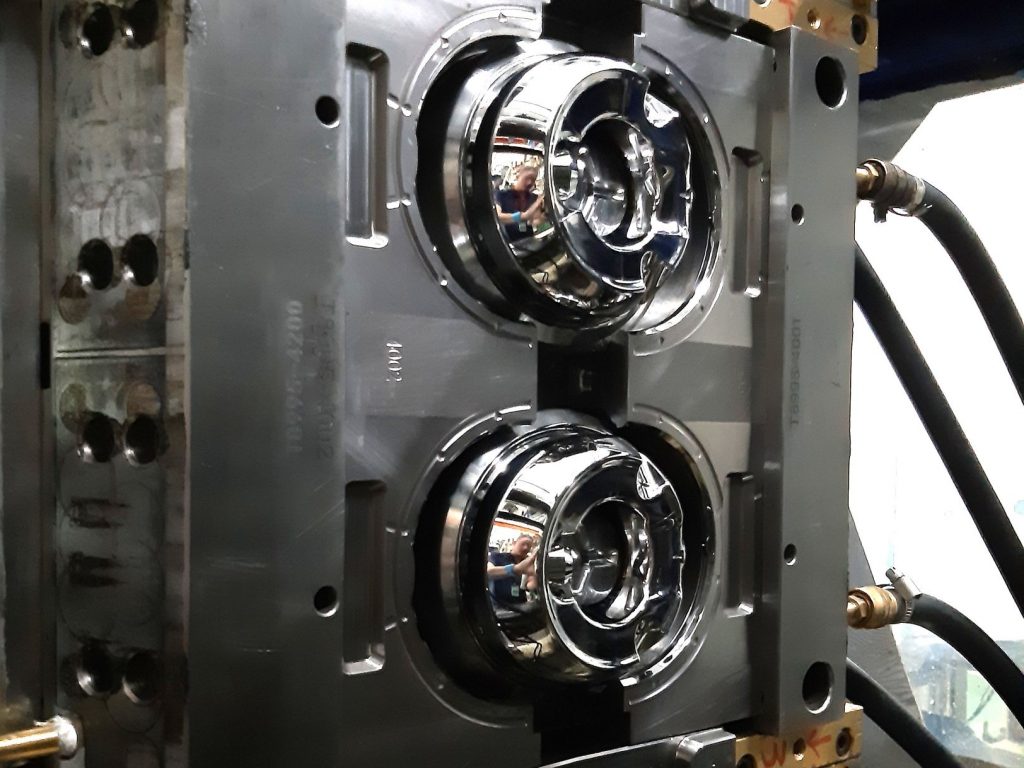

As well as managing the drawings, BOM and other specifications, with this being a food-contacting medical device, I had to collaborate closely with the quality team to ensure that critical parts were certifiably food-safe and/or bio-compatible. I also had to ensure that the design-release followed Elvie’s ISO 13485 procedures. Once the tooling neared completion, I spent a month on-site in China with our contract manufacturer, attending moulding trials, checking form/fit/function and CMF, supporting rapid design & process adjustments, then ultimately signing-off the tools & samples. The product was launched on time and on budget in 2024.