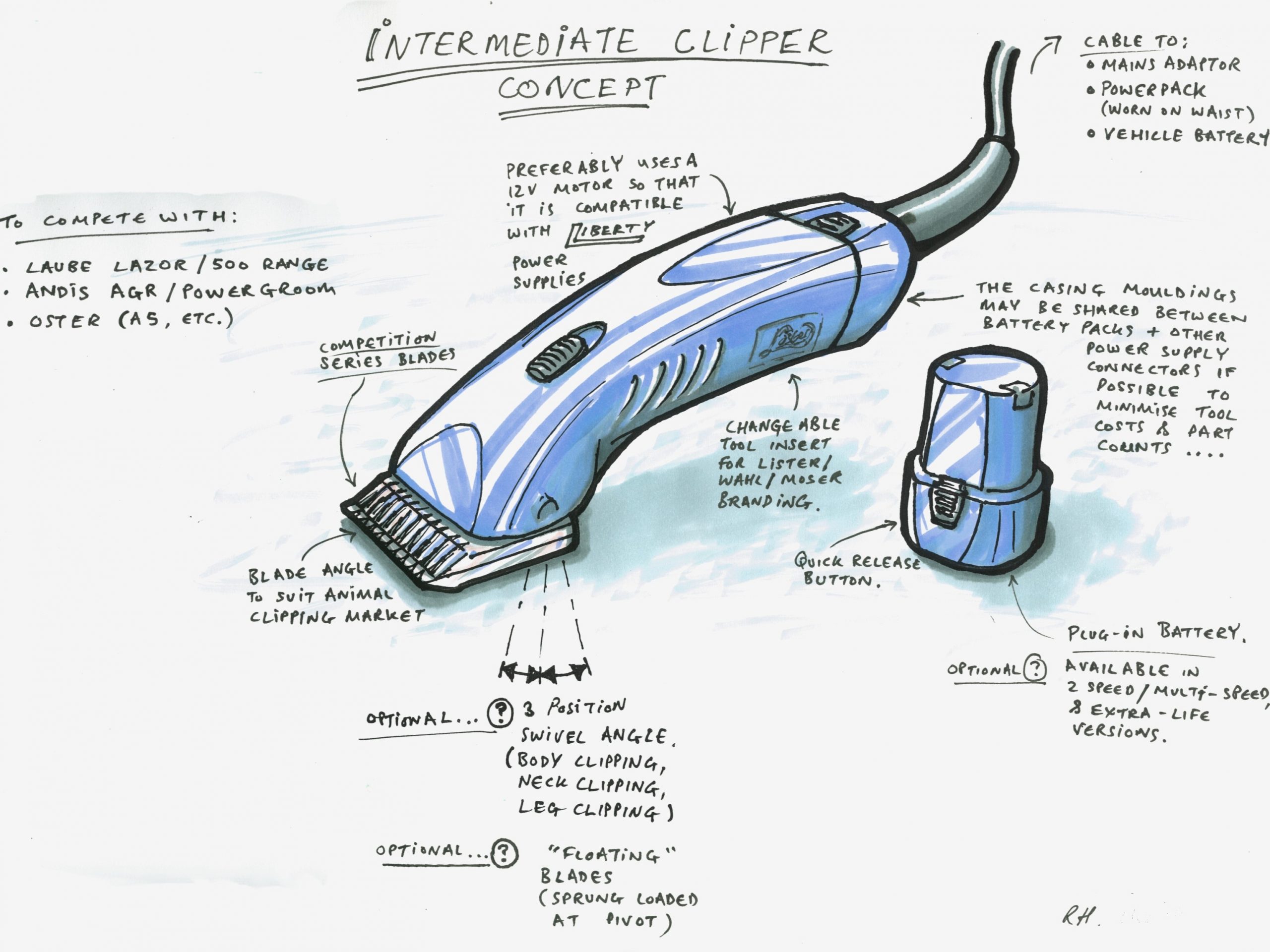

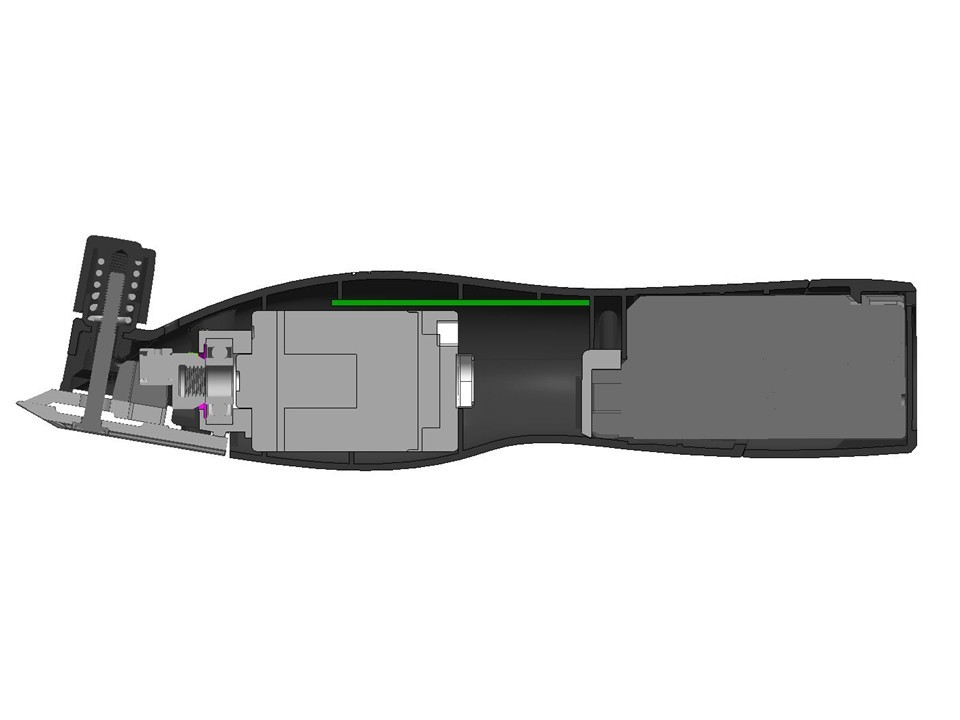

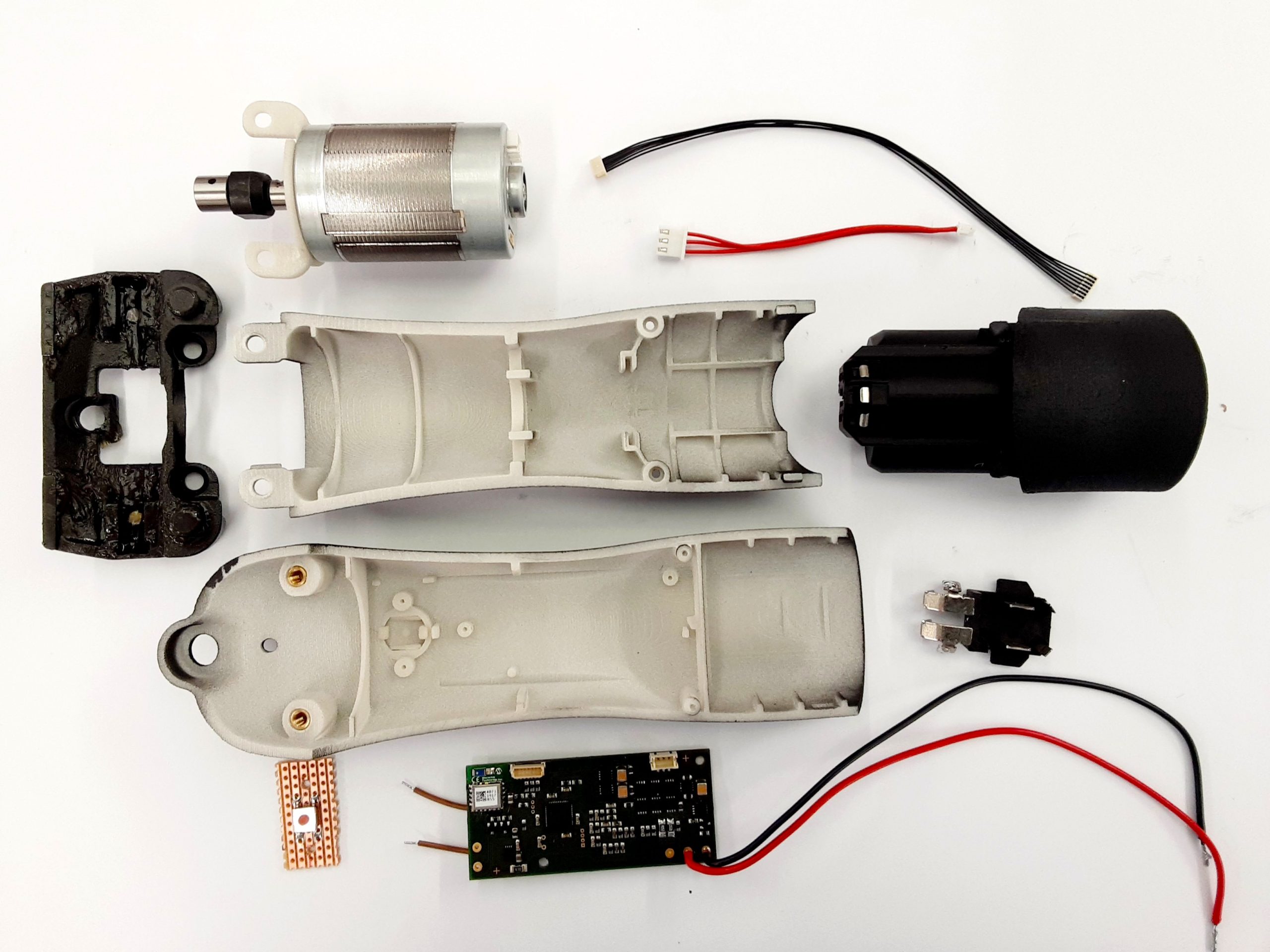

In developing the first cordless clipper to use Lister’s extra-wide clipping blades, the breakthrough came when I successfully hacked these blades onto the motor & handle of Wahl’s latest dog-grooming clipper. It functioned well enough to prove the key concept; the right brushless motor coupled with electronic torque-compensation could be powerful enough to eliminate the bulky gearbox found in all comparable clippers. As well as offsetting the cost of the motor & electronics, eliminating this gearbox massively reduced the length & weight of the clipper compared to its competition, creating a game-changing product, powerful & nimble enough to clip every part of the horse.

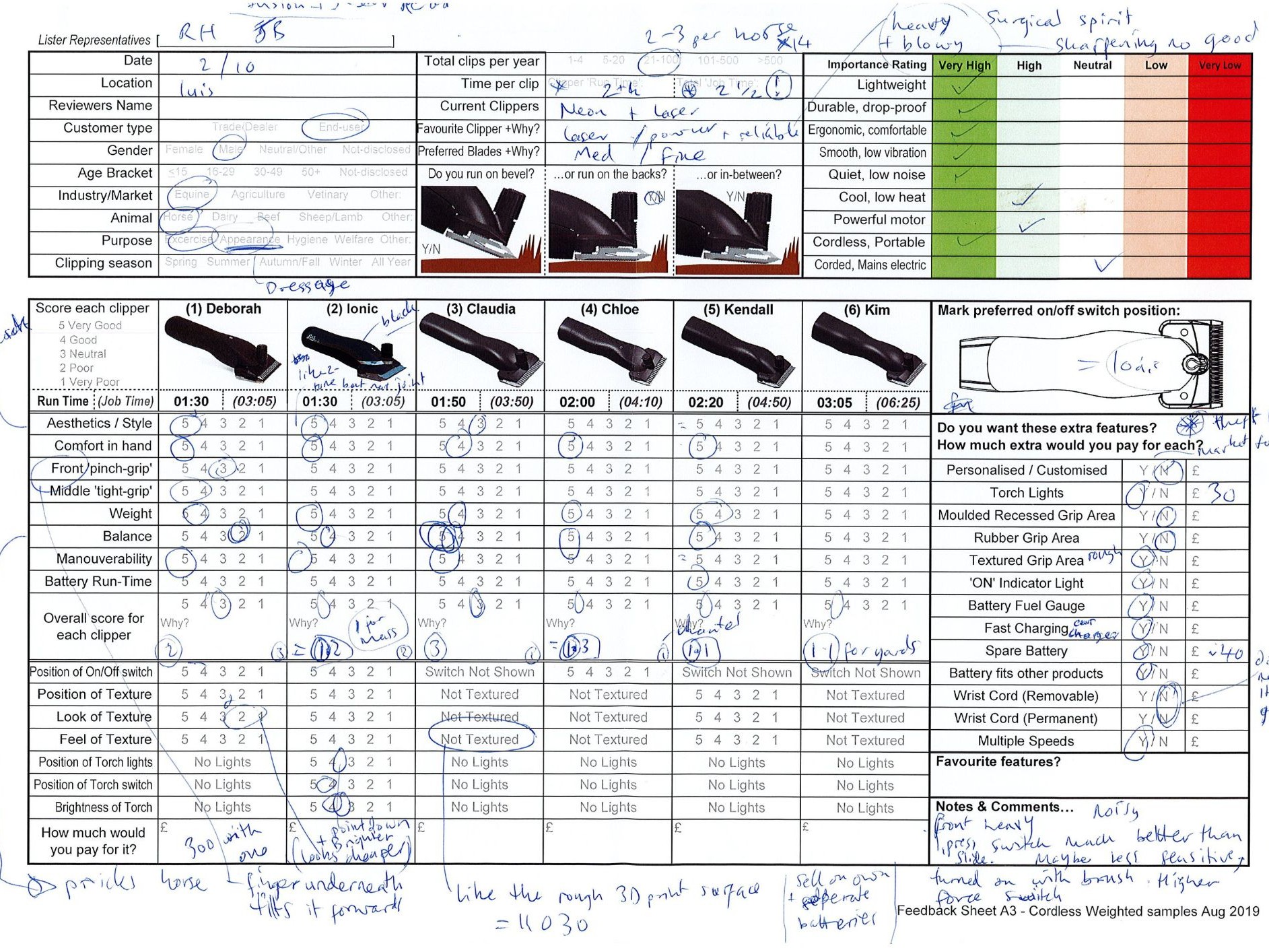

Working with our industrial designer, we explored a number of battery configurations to balance run-time against size & weight & cost, creating a family of weighted models and conducting a user research project to find the sweet spot. We worked directly with numerous amateur and professional grooms to test functioning prototypes in real life conditions, to help confirm and refine the design. Wahl’s electronics team remotely supported the PCBA and battery pack development, whilst I liaised directly with the motor manufacturer to specify the required upgrades. When I left in 2020, the electromechanical system was defined but the industrial design was still being finessed, so I was delighted when Lister successfully launched this product a couple of years later.