I joined this ambitious project just as it was transferring into mass production, spending many months in China providing engineering support on-site at the contract manufacturer. I helped both teams to collaborate through dozens of trouble-shooting and upgrade projects, engaging in a mixture of root-cause analysis, redesign, prototyping and testing activities (plus a healthy dose of international diplomacy).

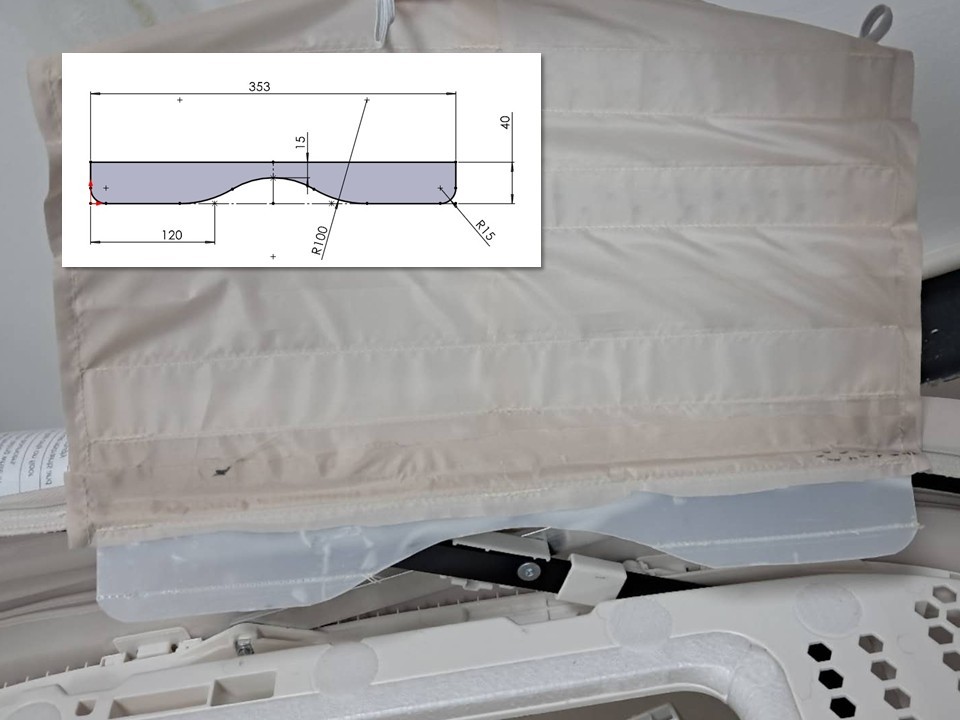

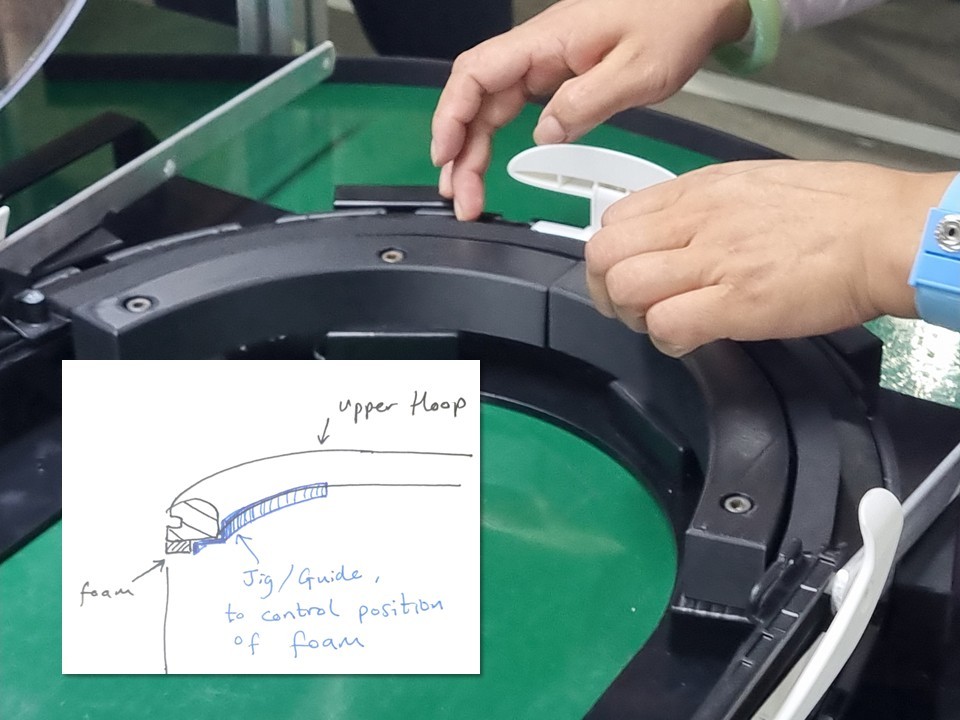

The main engineering focus was improving the performance and reliability of the bed transition and the harness-retraction mechanisms, which required a holistic approach as these systems are impacted by both the mechanical design and the textiles engineering.

During pre-production runs, I helped to review and sign-off the assembly line, identifying issues and offering potential solutions.

The most rewarding part of the project was immersing myself in the local culture and building connections with my Chinese colleagues, in a place where friendship and professional collaboration go hand in hand.